ウツワ

2020.02.27 THU.

Exploring the factory of “CARUSO” in Soragna for seeking an authentic community-based product making.

The previous article of the interview of Mr. Aldo Maria Camillo, the creative director, and Mr. Marco Angeloni, the CEO, followed by our visitation to their factory to scrutinize CARUSO’s product making. Their factory is located in a small town called Soragna in Parma, Italy, and their traditional philosophy since the brand’s establishment in 1958 and the latest manufacturing technology are perfectly harmonized. In addition, their production is deeply connected with lifestyles of the local residents. Today, we will travel through the factory of CARUSO with a guidance by Mr. Roberto Shibin, the manager of the pattern department.

Photo:Shunya Arai(YARD)

Text:Kai Tokuhara

―Hi Mr. Roberto. Could you start with telling us about your career till you entered CARUSO? And, please let us know about your current duties as well.

As my father used to manage a sartoria (tailor), I decided to attend a fashion school from that influence. When I was 19-year-old, I entered a small apparel firm that I started my career in the fashion industry. At the company, I was hugely attracted by a depth of a pattern making, so I determined to attend another fashion school to learn more after working in the firm for three years. After my graduation, I entered a company where my dad was working as a patterner. Thereafter, I met with CARUSO at the age of 25 and devoted six years as a patterner there. However, I moved to Zegna and spent nine years as a men’s patterner, but I came back to CARUSO again in 2011. Currently, I am the manager of 15 patterners at this factory in Soragna.

―In this factory, you guys manufacture CARUSO’s original merchandise as well as for the other maison brands as an OEM. What is your particular daily task like?

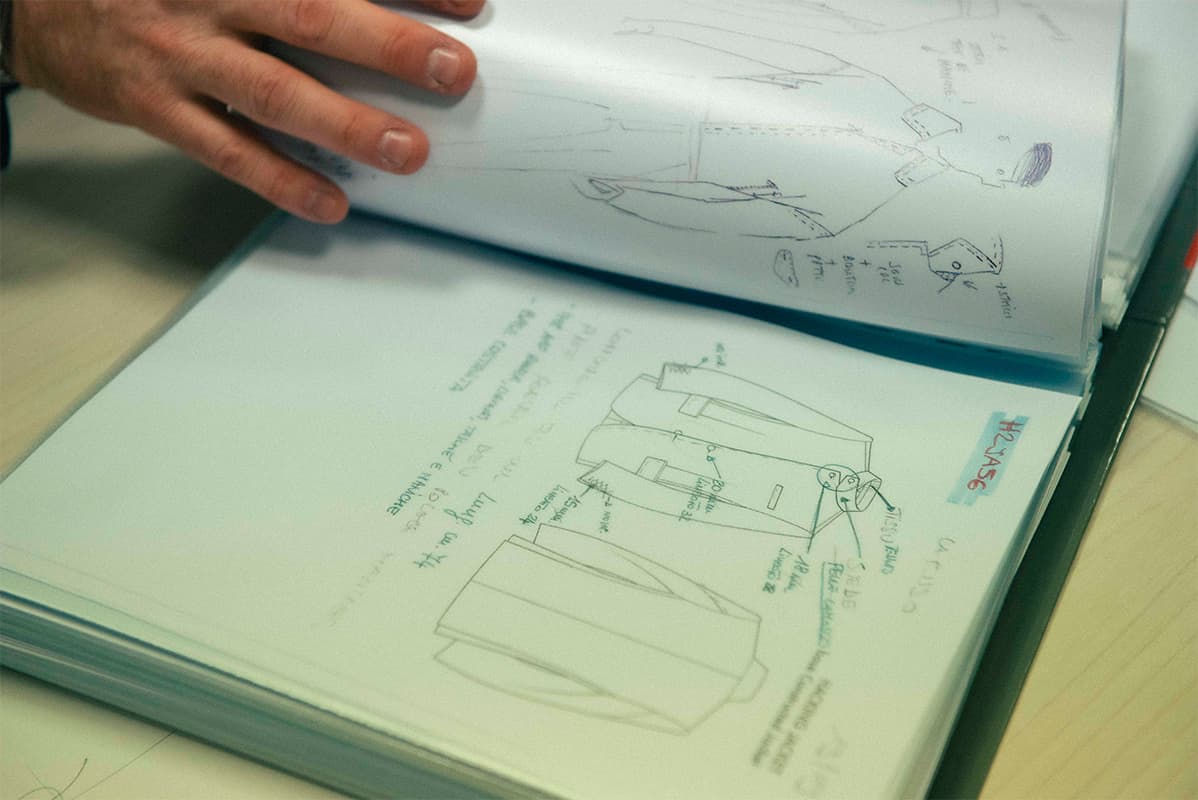

We basically prepare four collections per year for SS and AW seasons for both pre and main collections. And, my task is to produce a physical pattern based on an image that a designer comes up. Not only from a sketch, but I also communicate back and forth with a designer to visualize a pattern as thoroughly as possible. With the pattern, we create two prototypes, and the third piece becomes a completed sample. Yet, this process is actually much harder than you can imagine, so we are always fighting against a calendar. Especially, a jacket which CARUSO designs requires a time for technical details. Thus, the time management is also a big part of my work.

Please take a look at this. It’s a shoulder pad inside of a jacket, and this piece totally changes a figure. From thin to thick ones, the detail is infinite, and we have to select a perfect piece based on a request of a client which is not so easy as you can imagine haha.

―Here goes the factory part. Can you tell us about the history how was Soragna chosen for the manufacturing base?

Our history started with Raffaele Caruso, the founder, who built a small factory for a reinstatement in Soragna. He was from the southern part of Napoli, but his wife was from Soragna, so he moved here to establish this product making base. Thereafter, the business was gradually expanded, and Umberto, Raffaele’s son, and then Marco, Umberto’s son, inherited the firm in order.

―What is a philosophy that you share in the factory?

What we mainly manufacture here are classic jackets and trousers, but CARUSO also produces collections of the other brands, so we have to be flexible in various styles. And, that is a huge difference between us and the other conventional jacket makers. Our philosophy is definitely based on a sartoria, but we also try to incorporate fresh ideas of modern designers.

―Marco Angeloni, the CEO, told us that the harmony of handwork and technology is one of the biggest features of the CARUSO factory.

Absolutely. In fact, 255 processes are required for making a jacket and 80 processes for trousers, so I cannot explain every single method, but what I can insist is that technology is more efficient and accurate for some processes than handmaking. The balance is vital. A computer is supplied for each staff, and they can check updated schedules and order processes anytime.

―How do you train the craftsmen and staffs who work in the factory?

Staffs who work with us are affluent in their experiences that some of them are over the age of a usual retirement. Some are moved here from Napoli with Raffaele and their families work with us through several generations. And, young local workers learn from them. That cycle is spontaneously rooted in this area which is a very positive movement. Raffaele basically established a small town for the product making in Soragna for a community-based business. On top of that, the street right in front of the factory is named after him, “Raffaele Caruso Street”.

Soragna is a lowland which is located by Po River, also known as a humid area. Extremely hot during a summer and cold during a winter. The town remains with the atmosphere of a castle town from Medieval Europe.

Soragna is a lowland which is located by Po River, also known as a humid area. Extremely hot during a summer and cold during a winter. The town remains with the atmosphere of a castle town from Medieval Europe.

―Do you also live in Soragna?

I live in a town called Fidenza which is nearby. I met with my wife in this company, and actually, my father also met with my mother in an apparel company that they were working at. Coincidentally, I am like following the same story of my parents.

―What is a fascination of Soragna?

In fact, Soragna seems more like a little village and might look closed to some visitors, but it’s not true. People are very heartwarming, and culatello is a local specialty as the high humidity here is perfect for its production. And, CARUSO has been together with Soragna since 1958. Today, CARUSO is the symbol of Soragna that “CARUSO is Soragna, and Soragna is CARUSO,” and I am very honored to be a part of this society.

Click here for an interview with two key people from CARUSO.

PROFILE

Roberto Cibin

From Treviso, Veneto, Italy. With an influence of his father who used to manage a sartoria, he learnt pattern making at a fashion school and entered CARUSO when he was 25. After six years, he was in augurated as a patterner of the men’s department at Ermenegildo Zegna. In 2011, he returned to CARUSO, and currently, he manages the pattern making department, the core of the production, at its factory in Soragna.